Torque Transducers

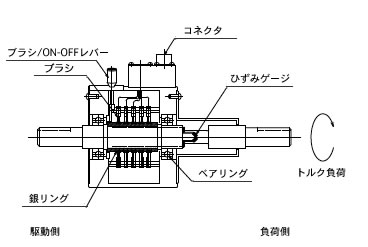

- Torque is generally called Force Moment and is expressed in the unit of “N•m”. Measurements by means of torque transducers are widely made in the motive power property tests, administration of combinable force relating to reliability or safety of the machinery parts, or quality controls including assessments of steering maneuverability force in various industries such as automobiles, railways, electricity, or industrial machines. Torque transducers are generally classified into the two large groups of rotating type and non-rotating type and their detecting mechanisms are various. But, any types of our products are relying on the strain gage type torque detection system and have advantageous features of being able to make detection of dynamic torque of very small mechanical torsional angle and of small response. In addition, because the physical units of torque is “N•m ” and also because force transducers can be used for torque measurement, torque detection can be made by means of load cells even in case when a torque transducer cannot be installed on an intended position on account of its structure.

-

Kinds of Torque Transducers

| Product image | Type | Structure and features | Rated range | linearity(%RO) | Rated output(mV/V) | Operating temperature(℃) |

|---|---|---|---|---|---|---|

|

TP-L | Reaction Torque type,Ultralow-Capacity,Aluminum alloy※1 | 1,..100 N•cm | 0.3 | 1mV/V(公称値) | -10~40 |

|

TP-R | Reaction Torque type,Low-Capacity,High stiffness,Aluminum alloy※1 | 50,..1000 N•cm | 0.2 | 1mV/V(公称値) | -10~40 |

|

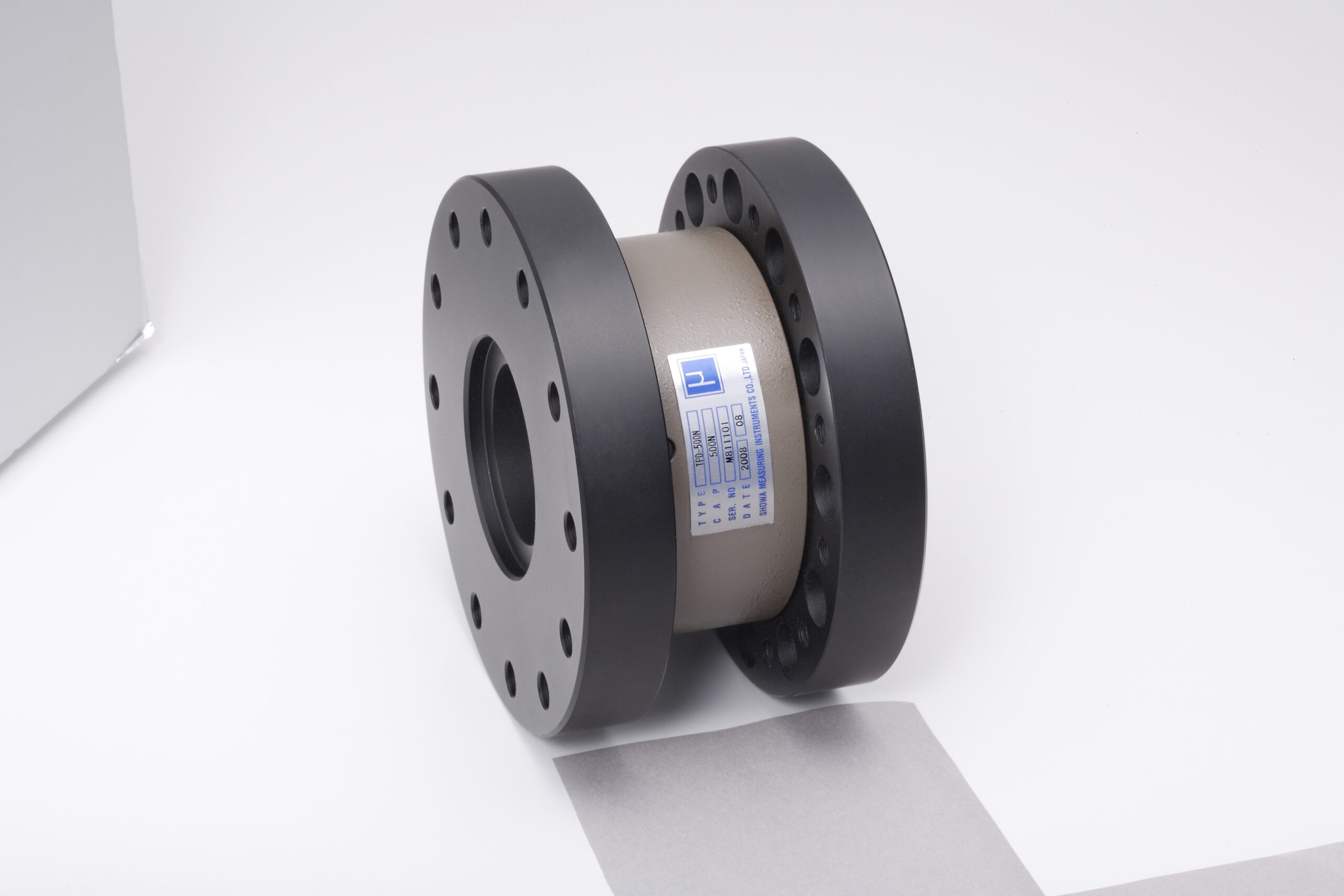

TP | Reaction Torque type,High stiffness,Flange at both ends,General Purpose | 50,..20 kN•m | 0.2 | 1.0±1 % | -10~60 |

|

TQP | Rotary Torque type(with Slip-ring assemblies),General Purpose※1 | 5,..20 kN•m | 0.3 | 0.5,1.0,1.5±1 % | -10~60 |

|

TPD | Non-rotating, thin, highly rigid, flanged at both ends*1 | 500,..10 kN•m | 0.2 | 1.0±1 % | -10~60 |