Company Overview

Company Overview

| Company name | SHOWA MEASURING INSTRUMENTS Co., Ltd. |

|---|---|

| Established | Feburuary 1962 |

| Capital | 40 million yen |

| Business details | Design, development, and manufacture of strain gauges and transducers |

| Board of directors | Akio Morikawa, President and CEO Hiroshi Mikami, director Takehisa Inoyama, Outside director |

| Employees | 90(50 men, 40 women) |

| Lines of business | Strain gauges, load transducers, 6-component force transducers, pressure transducers torque transducers, digital display gauges, dynamic strain amplifiers |

| Business locations | Main office; 1-17-16 Nishihokima, Adachi-ku, Tokyo Plant; 5-24-27 Hokima, Adachi-ku, Tokyo Osaka Sales Office; Shin-Miwa Bldg,. 1-5-16 Enokojima, Nishi-ku, Osaka |

| Banks | Bank of Tokyo-Mitsubishi UFJ,Resona Bank |

| Affliated companies | Showa Seimitu Inc. ESA Inc. |

History

| 1949 | Resarch on resistance-wire strain gauges begins for the first time in Japan at the Transport Research Institute. |

|---|---|

| 1950 | Wire gauges and static strain gauges are completed at the aforementioned Institute. |

| 1960 | Design of electric scanning strain indicator |

| 1961 | R&D for the purpose of commercializing foil strain gauges. |

| 1962 | Showa Measuring Instruments Research Institute Co., Ltd. is established. Manufacturing of foil strain gauges, pressure meters and all kinds of measuring instruments begins. |

| 1964 | Main office and plant move to Nakamaru-cho, Itabasi-ku Tokyo. |

| 1967 | Osaka branch office is established. |

| 1969 | Nagoya branch office is established. |

| 1970 | Main office and plant move to Shimura, Itabashi-ku, Tokyo. |

| 1970 | Company name is changed to Showa Measuring Instruments Co., Ltd. |

| 1972 | Mejiro Plant is newly established. Dedicated production of foil gauges begins. |

| 1973 | Hokima Plant is established at Nishihokima, Adachi-ku. |

| 1981 | Main office moves to 1-17-16 Nishihokima, Adachi-ku. |

| 1990 | Construction of new planmt completed at 5-24-27 Hokima, Adachi-ku. Production streamlining of load,pressure,and torque transducers. |

| 1990 | Development of small, lightweight 6-component force transducer. |

| 1992 | Capital increases to 40 million yen. |

| 1998 | Calibration certification is obtained from JCSS(as a measurement researchlaboratory) for 20 kN and 200 kN force calibration machines. |

| 2001 | ISO 9001 certification is obtained. |

| 2002 | Accreditation is obstained as a JCSS “force” accredited company. |

| 2008 | ECO Action 21 certification is obstained. |

| 2015 | Certified as an MRA-compliant JCSS-accredited operator. |

| 2021 | Start of high capacity calibration service with introduction of 5MN force reference machine. |

| 2022 | Kyoto sales office established, Osaka sub-branch closed. |

Head office/offices and factories

For telephone enquiries about our products, please contact the following sales office.

For enquiries by e-mail, please use the enquiry form.

-

Head office/Tokyo sales office

1-17-16 Nishihokima, Adachi-ku, Tokyo 121-0812

tel 03-3850-5431 fax 03-3850-5436

Area covered: Shizuoka, Nagano, Ishikawa and eastwards…

-

Kyoto Sales Office

4F Reno Court, 403-3 Higashi-Uratsuji-cho, Kamigyo-ku, Kyoto, 602-8031, Japan

tel 075-256-8757 fax 075-256-8758

Area covered: Aichi, Gifu, Fukui and westwards…

-

Factory

5-24-27 Hokima, Adachi-ku, Tokyo 121-0064

tel 03-3858-3241 fax 03-3859-1240

-

-

Panoramic view of the factory

1F: Adjustment, inspection and calibration of load cells, pressure transducers, torque transducers, etc.

2F: Outgoing inspection, quality assurance, factory operations

3F: Clean room, assembly line mainly for standard transducers

4F: Design department, conference room, calibration room

-

-

Cleanroom

Strain gauges are bonded at a cleanliness of 10 000 and at a constant temperature and humidity.

-

-

Main equipment

5MN Amsler compression testers / 500KN Amsler compression testers / 200KN switching force standard (jcss) / 20KN switching force standard (jcss) / 50MPa deadweight pressure standard / 5MPa deadweight pressure standard / 20kNm torque tester / 2kNm torque tester / Gauge Blocks (1mm – 200mm) / Reference weights (5g – 20kg) / Ultra-precision digital multimeters / Ultra-precision digital static strainmeters / Ultra-precision digital static strain calibrators / Standard voltage generators / High precision photo-etching machines / Programmable constant temperature chambers / etc.

Technical support

Questions about strain gages/strain gage transducers and measurement are welcome.

Please use the enquiry form to contact us.

Quality assurance system

Showa Sokki’s basic policy on quality assurance is to provide products that satisfy customers. The concept of quality assurance does not stop at guaranteeing standards and performance as a ‘thing’, but is interpreted as something that can only be obtained by providing products that meet the requirements of the customer. We have a very wide range of strain gages and applied sensors, but we aim to “manufacture products that satisfy our customers” not only by providing standards and performance in our catalogue, but also by proposing and following up on the best products through communication. In February 2001, we acquired ISO 9001 quality system certification, and we are confident that this will enable us to further respond to the trust of our customers.

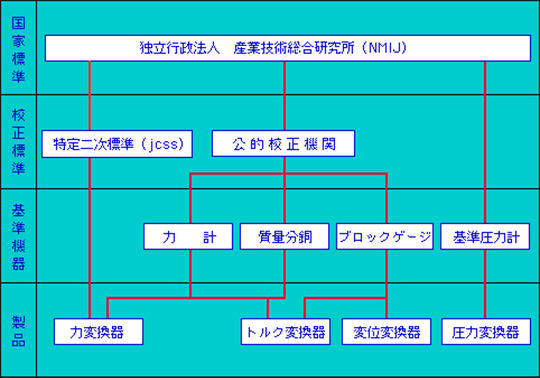

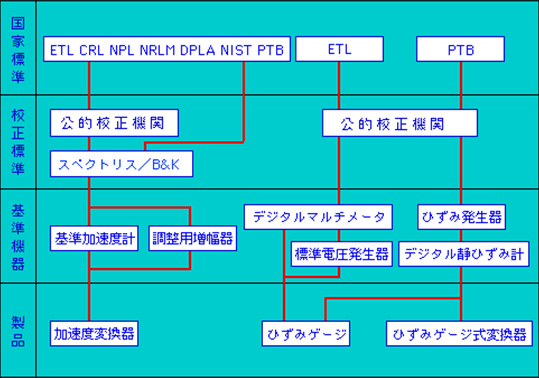

Traceability system

All products delivered to customers are tested and inspected based on a traceability system, which is indispensable for quality assurance.Recently, load cells and other transducers have been used in large numbers not only for testing and research purposes but also as quality control equipment on production lines, and we strive to maintain and control testing and inspection equipment in the manufacturing process to ensure that our customers can use our products with confidence.

ETL: Electronics Technology Laboratory, Industrial Technology Research Institute, Ministry of International Trade and Industry (MITI)

NPL: National Physical Laboratory, UK

NIST: US Federal Bureau of Standards and Technology

CRL: Communications Research Laboratory, Ministry of Posts and Telecommunications

DPLA: Danish Primary Laboratory of Acoustic

PTB: German National Institute of Science and Technology

JCSS accreditation (accreditation no. 0112)

Showa Sokki Calibration Laboratory Co., Ltd. is accredited as a ‘force’ accredited business (June 2002).JCSS accredited business operators are accredited by the Minister of Economy, Trade and Industry and can provide JCSS calibration services to general users using specified secondary standards that have been calibrated by specified standards etc. They are mainly used for the calibration of high-precision load cells and load cells for load verification with the JCSS logo mark, and calibration is carried out by dedicated calibration operators.